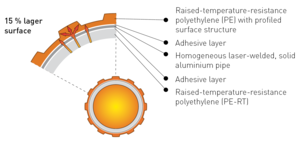

The VarioProFile pipe uses the advantages of both aluminium and plastic. It combines five interconnected layers. That guarantees a slightly flexible yet dimensionally stable pipe.

The innermost layer is made of polyethylene and temperature resistant. The inner surface is smooth as glass, making it impossible for deposits to form. The water flows through the pipe without resistance and with minimal pressure losses.

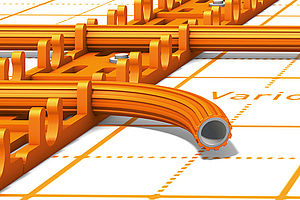

The profiled surface structure increases the outermost layer of the pipe by up to 15%. The larger surface means optimised heat transfer compared with other pipes with the same diameter.

Airtight and in shape

100% oxygen diffusion-tight thanks to the laser-welded aluminium pipe: The metal prevents oxygen penetration.

That virtually rules out potential silting.

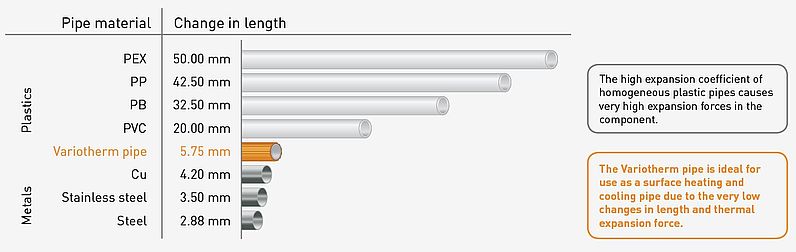

The aluminium layer guarantees elongation up to nine times lower than PEX pipes. That means the VarioProFile pipe is ideal for surface heating and cooling systems.

This is what the VarioProFile-pipe looks like

Flexible applications

The VarioProFile pipe is as flexible as the Variotherm world of products itself and is used in the following systems:

Creep rupture properties

The creep behaviour indicates the long-term heat resistance of the VarioProFile pipe. This behaviour has been scrutinised in a creep rupture test. It is very important for heating piping as this is exposed to high temperatures over long periods.

Scrutinised creep behaviour has been tested for a service life of 50 years.

Technical data

Pipe diameter: 16 mm

Pipe wall thickness: 2 mm

Aluminium pipe thickness: 0,15 mm

Roll length: 100, 300 and 500 m

Water content: 0,113 l/m

Special narrow bending radius (usea suitable bending device): 48 mm

Max. operating temperature [tmax]: 70 °C

Short-term resistant [tmal]: 95 °C

Max. operating pressure [pmax]: 6 bar

Linear expansion coefficient: 2,6 × 10-5 [K-1]

Mean heat conduction coefficient [λ]: 0,43 W/mK

Heat transmission resistance: 0,0043 m²K/W

Advantages at a glance

- Profiled surface structure for optimised heat transfer

- First-class plaster adhesion for wall heating systems

- Fully corrosion-free

- Optimum creep behaviour

- High thermal conductivity

- High pressure and temperature resistance (6 bar, +70°C)

- Flexible, easy to bend, extremely good hydrostatic stability

- 100 % oxygen diffusion-tight

- Resistant to hot water additives

- Mirror-smooth inner surface – less pressure loss – no encrustation

- Lower linear coefficient of expansion, lower heat expansion forces

- 10-year guarantee with certificate