Everything you need to know about the technology and installation

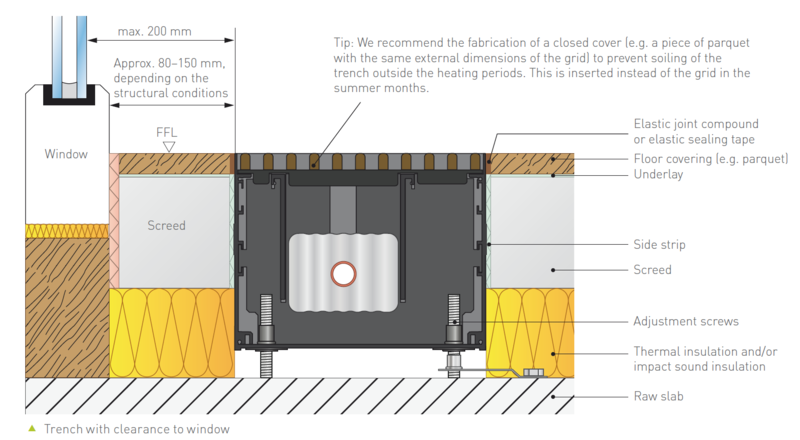

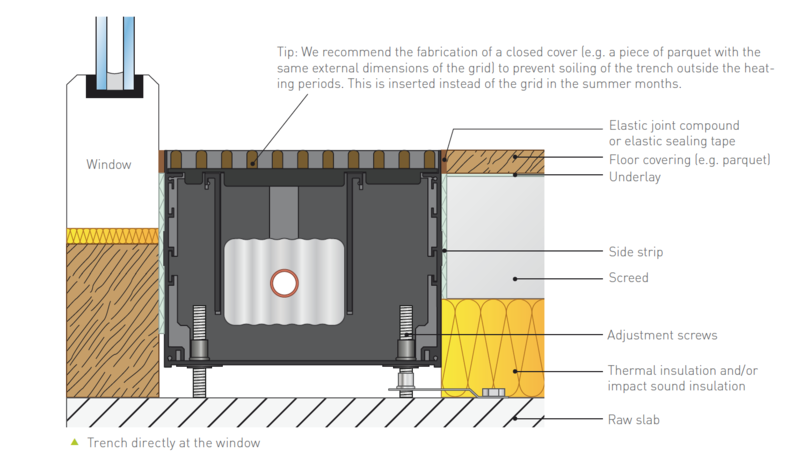

This is how trench heating is constructed

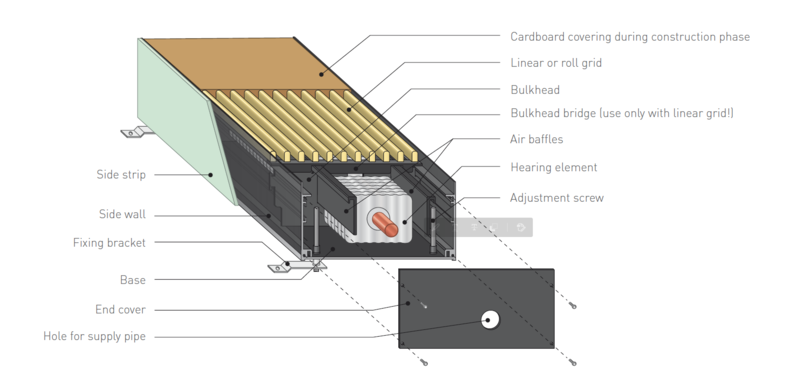

The trench heating system is supplied pre-assembled, ready for installation. All components are perfectly matched to each other.

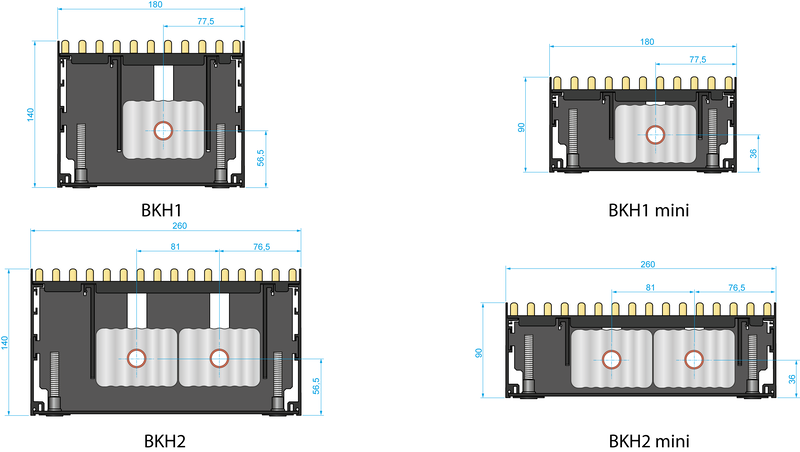

- Floor trench: Aluminium side walls and end cover (black anodised), black-grey aluminium base, air baffles, heating element mounting bulkheads, interior adjustment screws for height adjustment, green side strips, attachment brackets

- Length: Custom length (with lengths > 5000 mm, the floor trench is supplied in segments)

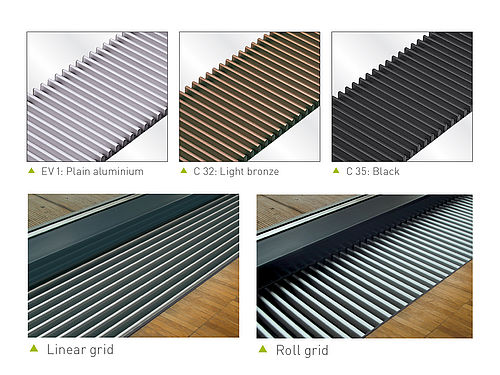

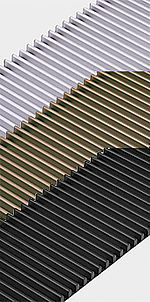

- Grid: Linear or roll grid, anodised aluminium, safe to walk on, standard colours: Plain aluminium (EV 1), light bronze (C 32), black (C 35)

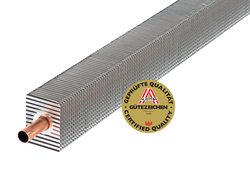

- Heating element: Copper pipe ø 18 × 0.5 mm (DIN EN 12 449) with 56 × 78 mm aluminium louvres

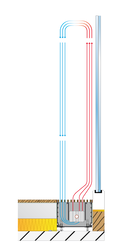

The Coandă-Effect

The gentle warm air veil circulates along cold surfaces in particular. The air is better distributed and only sinks slowly in the room. There is therefore no significant air circulation.

Variotherm trench heaters are mounted directly on glass surfaces or cool walls. This enables a veil of warm air to quickly build up along the cold surfaces, leaving the cold outside.

Details and components

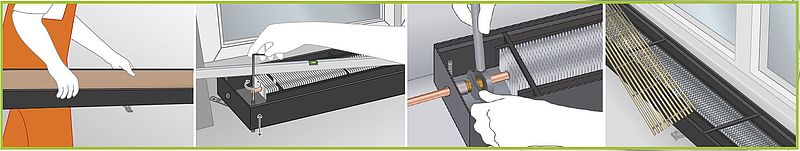

All Variotherm trench heating systems are delivered already pre-assembled with the correct length, and only need to be aligned and screwed into place at the designated site. Variotherm flow and return valves or 3/4" connection angle pieces can also be optionally pre-fitted to the pre-insulated VarioModular pipe.

The supply line holes are drilled in the end cover or side walls, as desired by the customer.

Heating elements

The heating elements are the technical core component of the Variotherm trench heating system. They work very efficiently and give off the heat optimally.

The heating element consists of a copper pipe ø 18 × 0.5 mm (DIN EN 12 449) with aluminium louvres 56 × 78 mm. The special manufacturing process results in a connection between the pipe and the aluminium louvres with an unsurpassed performance.

Dimensioning and layout

The dimensioning of the trench heating system depends on:

- The flow temperature

- The required output

- The possible installation length

Planning the maximum flow temperature tv of the heating system is the key to a healthy warmth provided by the trench heating system. We recommend that the set-up temperature does not exceed 60 °C. Otherwise, the louvre temperature will be significantly below the dust carbonisation temperature, which can lead to unhealthy air. Best results are achieved with maximum flow temperatures of 50 to 55 °C.

Ideal case:

Optimum cold shielding is achieved when the trench heating system is installed along the entire glass surface (floor-touching glass surfaces such as in winter gardens or terrace doors).

Recommended maximum length of a heating circuit:

BKH1, BKH1 mini: 7.5 m (= 7.5 m heating element)

BKH2, BKH2 mini: 5.0 m (= 10 m heating element)

Wer die Bodenkanalheizung mit einer Flächenheizung (Boden, Wand, Decke) kombiniert, deckt den Wärmebedarf gänzlich ab und erreicht ein rundum behagliches Raumklima.

Simple and quick to install

All Variotherm trench heating systems are delivered already pre-assembled with the correct length, and only need to be aligned and screwed into place on site. Using the interior adjustment screws, the trench can be precisely set to the required floor level. Subsequent adjustments can be made at any time. No underfill is required.

After connecting the trench heating system to the heating circuit, the screed and then the floor covering can be laid. Once the linear or roll grids have been inserted, the trench heating can be walked on immediately.