Everything you need to know about the technology and installation

- This is how floor heating is constructed using drywall construction

- VarioProFile-Pipe 11,6 x 1,5 – the aluminium multi-layer composite pipe

- Tested and certified

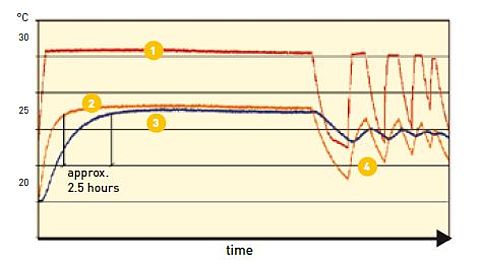

- Quick reaction time

- AR - 3D

- Prerequisites as a suitable substructure

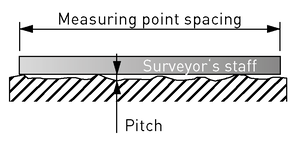

- Pipe spacing and piping

- Ideal floor coverings for floor heating

- Simple and quick to install

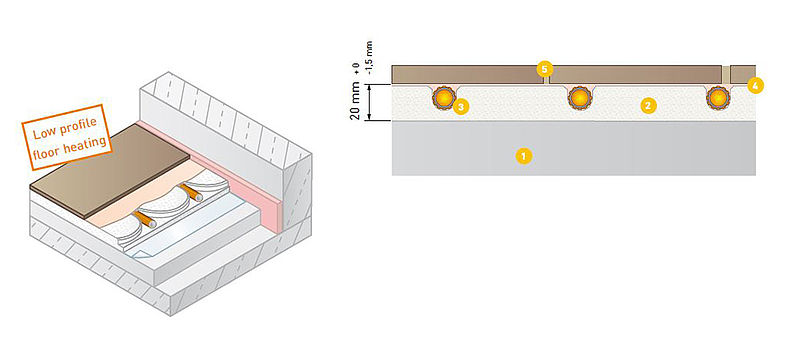

This is how floor heating is constructed using drywall construction

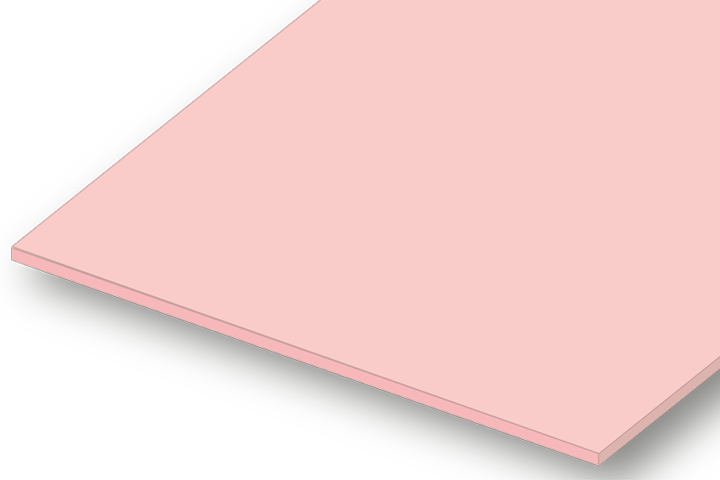

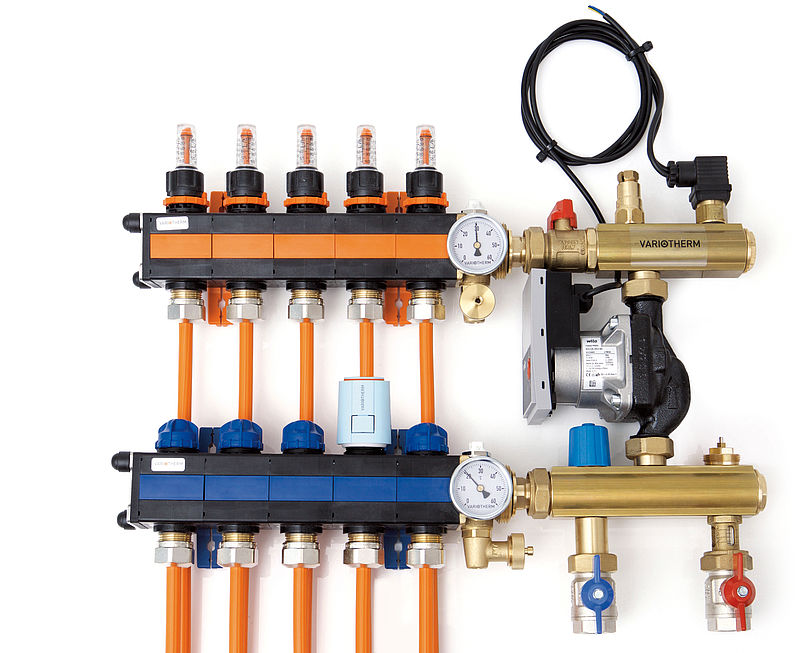

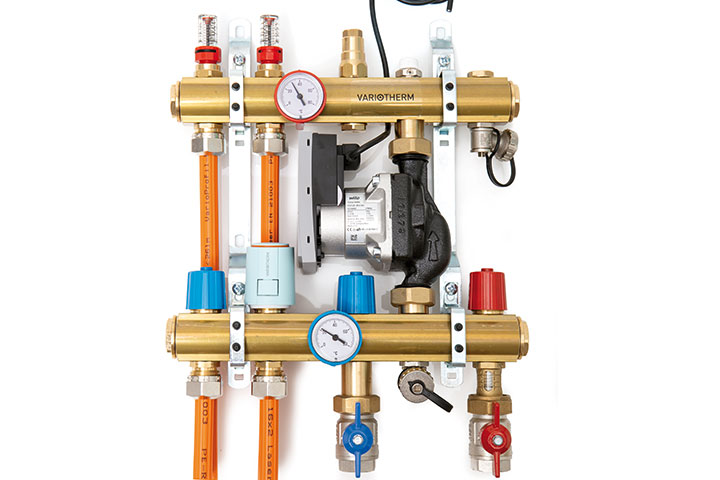

If you want to retrofit floor heating, install the VarioComp floor heating system. All components in this complete drywall construction system are perfectly matched and weighs only 25 kg/m2:

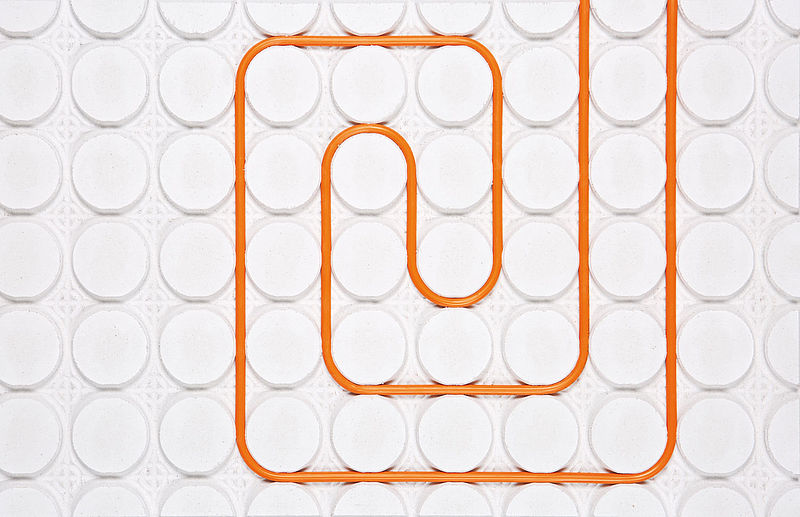

- The specially milled routings on the VarioComp panels

- The easy to bend VarioProFile pipe with an extremely stable form (aluminium multi-layer composite pipe)

- The fast-drying VarioComp filling compound

- The height of the optional XPS and Silent underlay panels

Construction:

1. Substructure

2. VarioComp panel 600 x 1000 mm

3. VarioProFile pipe 11.6 x 1.5

4. VarioComp filling compound

5. Floor covering

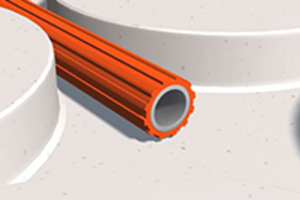

VarioProFile-Pipe 11,6 x 1,5 – the aluminium multi-layer composite pipe

The VarioProFile pipe uses the advantages of both aluminium and plastic. It combines five interconnected layers. That guarantees a slightly flexible yet dimensionally stable pipe.

The innermost layer is made of polyethylene and extremely temperature resistant. The inner surface is smooth as glass, making it impossible for deposits to form. The water flows through the pipe without resistance and with minimal pressure losses.

The profiled surface structure increases the outermost layer of the pipe by up to 15%. The larger surface means optimised heat transfer compared with other pipes with the same diameter. >>> more

Now available: Experience the VarioComp in 3D and Augmented Reality!

Now you can explore our VarioKomp virtually:

- In 3D: Admire our Variokomp from the perspective that is relevant to you.

- In AR: Have your smartphone at hand - scan the QR code and hold it in the room. The product is now virtually simulated in the room. The optimal companion for the construction site.

Pipe spacing and piping

The VarioComp panels can be laid with the following pipe spacings:

- 100 mm pipe spacing: Living rooms and barefoot areas – this way it’s comfortably warm.

- 150 mm pipe spacing: For example in workshops, shed spaces, offices, etc. – for all rooms where we don’t walk barefoot.

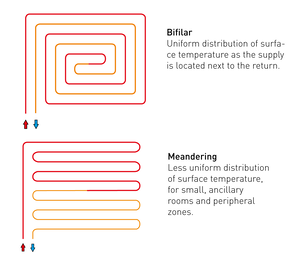

The VarioProfile pipe 11.6x1.5 (aluminium multi-layer composite pipe) can be laid in bifilar or meander form.

The maximum pipe length per heating circuit including supply pipe is 80m. 100 mm pipe spacing requires 10 m/m². If the heating pipe is laid with 150 mm spacing, you need to allow for 6.7 m/m².

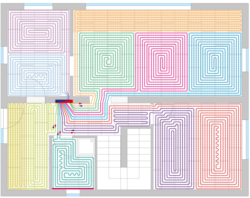

Laying example

This is how the floor heating can be installed using drywall construction: example of a family house where the heating pipe was laid continuously with 100 mm pipe spacing.

The peripheral zone starting in front of a large glass surface or glass doors, a meander pattern layout goes along the glass surface, reaching into the room by about 1¬metre. This will lead to a higher surface temperature in front of the glass surfaces (Variotherm comfort tip).

Ideal floor coverings for floor heating

The surface of the VarioComp floor heating system complies with ÖNORM DIN 18202.

You can lay whichever floor covering you like, whether it’s stone, wood, laminate and multi-layer parquet, ceramic tiles, linoleum or carpet. It’s important that the floor covering is suitable, according to the manufacturer’s information.

In general, the thicker the covering, the slower the heat transfer, since the floor has to be heated up for longer. For example, tiles and natural stone have a high thermal conductivity and quickly radiate heat into the room.

The floors should have a maximum thermal resistance of 0.15 m²K/W. Variotherm’s recommendation: ≤ 0.1 m²K/W.

Simple and quick to install

The 18 millimetre-thin gypsum fibre boards are laid on a flat and load-bearing substructure using drywall construction. These VarioComp panels have specially milled routings. This enables the VarioProFile pipe 11.6x1.5 (aluminium multi-layer composite pipe) to be laid individually. This guarantees even pipe spacing. At the same time, the pipe is firmly fixed between the routings. The heating pipe can be laid in meander or bifilar form.

Finally, the special VarioComp filling compound is poured on and levelled. The floor covering can already be laid after a short drying period (after around 24 hours). Any surface is possible: wooden parquet, tiles, stone flooring, laminate or carpet.