Everything you need to know about the technology and installation

- This is how a ceiling cooling/heating system is constructed using drywall construction

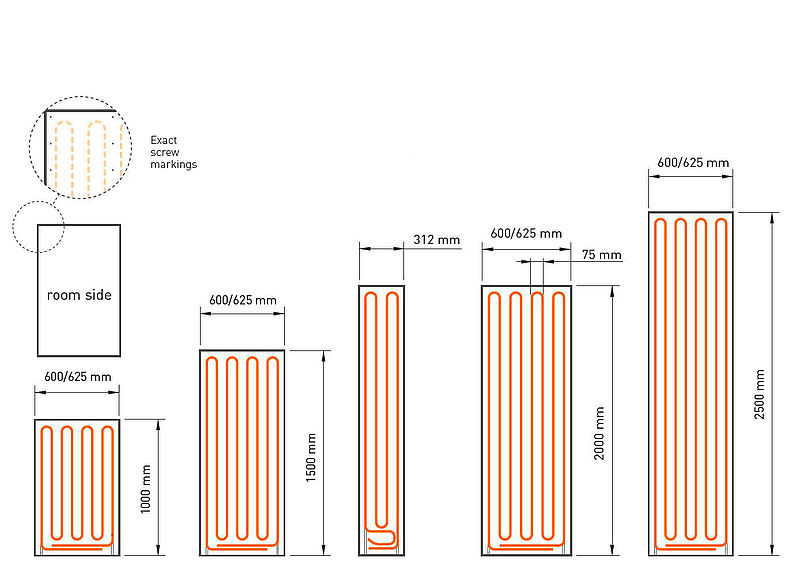

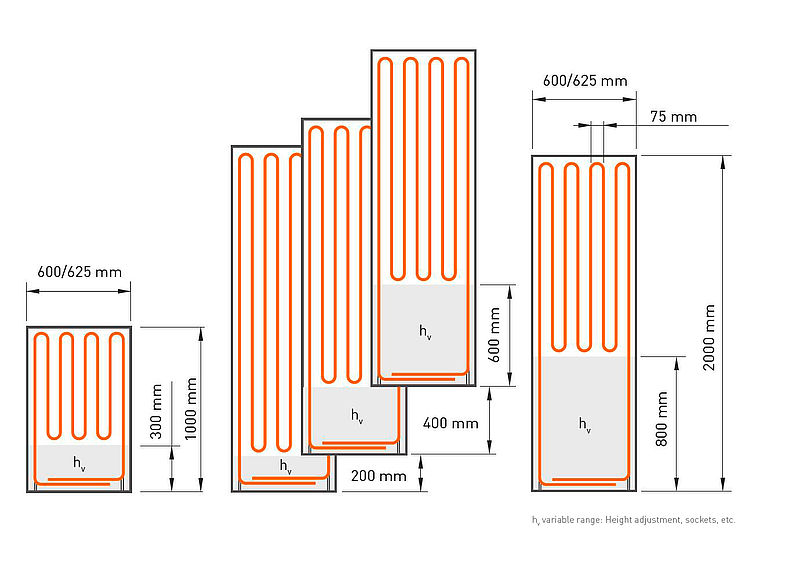

- Flexible panel formats for quick assembly

- AR - 3D

- Certified fire protection panel

- ModulePanel technical data

- Arrangement of the cooling/heating surfaces

- VarioModule-Pipe 11,6x1,5 Laser – aluminium multi-layer composite pipe

- Wooden or metal substructures

- Simple and quick to install

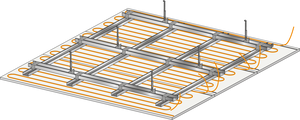

This is how a ceiling cooling/heating system is constructed using drywall construction

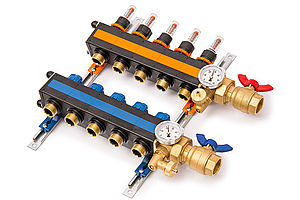

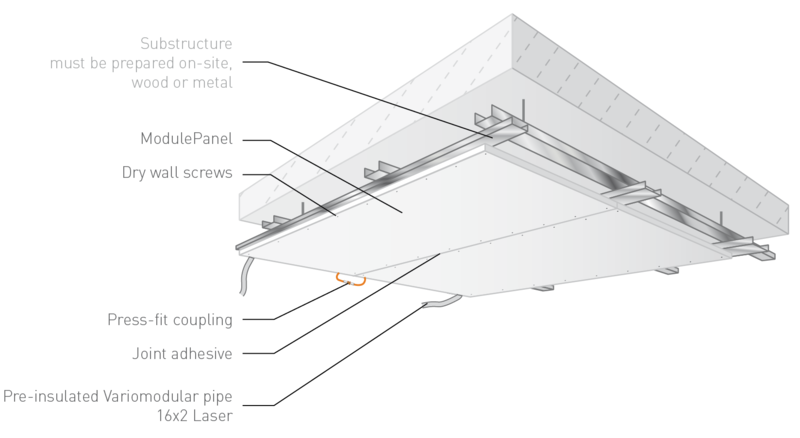

The cooling ceiling consists of a flexible panel system made of ecologically tested gypsum fibre boards. The Variomodular pipes (aluminium multi-layer composite pipes) are already integrated in the rear of the panels. It is a cooling system and ceiling in one. If it is connected to a heat source in winter, it provides ceiling heating.

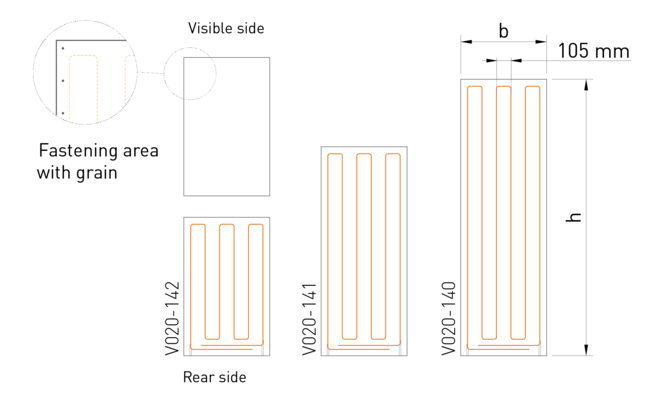

3 panels with a fixed height. Pipe spacing 105 cm

These ModulePanels have pipe spacing of 105 mm. Recessed lights, smoke alarms, loudspeakers etc. are easy to install. These are inserted between those aluminium multi-layer composite pipes, while the remaining heating and cooling surfaces are laid with ModulePanels with 75 mm pipe spacing.

Now available: Experience the ModularCeiling in 3D and Augmented Reality!

Now you can explore our ModularCeiling virtually:

- In 3D: Admire our ModularCeiling from the perspective that is relevant to you.

- In AR: Have your smartphone at hand - scan the QR code and hold it in the room. The product is now virtually simulated in the room. The optimal companion for the construction site.

Certified fire protection panel

The Variotherm ModulePanel has preventive and defensive fire protection properties. It is important that components withstand fire for a specific period. The Variotherm ModulePanels have been certified as fire protection panels by the Institute for Fire Protection Technology and Safety Research Linz (IBS).

From a fire protection perspective, the 18 mm-thin ModulePanels correspond to a 12.5 mm FERMACELL gypsum fibre board panel (Test IBS-Linz No. VFA2001-0389.01, fire protection assessment file number 10111710).

ModulePanel technical data

Panel: The ecologically tested gypsum fibre board consists of recycled paper fibres, gypsum and water (without binding agents). The components are pressed under high pressure to form a stable and odourless board.

Apparent density ρK: 1150 ± 50 kg/m³

Water vapour diffusion resistance factor μ: 13

Thermal conductivity λ: 0,32 W/mK

Specific heat capacity: c = 1.1 kJ/kgK

Brinell hardness: 30 N/mm²

Thickness swelling after 24h water storage: < 2%

Thermal expansion coefficient: 0.001 %/K

Expansion/shrinkage when the relative humidity changes by 30 % (20 °C): 0.25 mm/m

Equilibrium humidity at 65 % relative humidity and 20 °C air temperature: 1.3 %

pH value: 7-8

Fire resistance as per DIN EN 13501-1: non-flammable, A2

Identification as per DIN EN 15283-2: GF-I-W2-C1

Arrangement of the cooling/heating surfaces

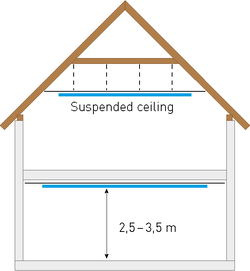

Ceilings and roof slopes are ideally suited for use as cooling and heating surfaces because the radiant surfaces are not obstructed by room furnishings.

Experience shows that comfort is perceived up to 3.5 m from the active cooling surface. In higher rooms the ceiling should be suspended because the radiant effect on the body declines in proportion to the square of the distance. Our tip: Supplement the ceiling cooling/heating with wall heating/cooling.

Estimated values for dimensions:

- 70–80% ceiling surface of the room area for cooling.

- 50–60% ceiling surface of the room area for heating.

Observe the heating/cooling load calculation for precise dimensioning of the area required!

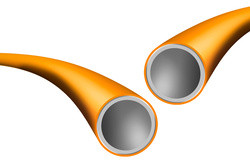

VarioModule-Pipe 11,6x1,5 Laser – aluminium multi-layer composite pipe

The Variomodular pipe (aluminium multi-layer composite pipe) has five layers that are connected to each other. That guarantees a highly flexible yet dimensionally stable pipe.

The laser-welded pipe is 100 % oxygen diffusion-tight. The metal prevents oxygen penetration, which virtually rules out potential silting.

The aluminium layer guarantees up to nine times less linear expansion than conventional plastic pipes.

Wooden or metal substructures

The substructure made of timber studs or metal profiles forms the basis for the ceiling cooling/heating. The structure can be constructed with or without surface panelling or cavity insulation and vapour retarders (vapour barrier).

Please note:

- With wooden constructions, the timber used must be sufficiently dry and straight, and conform to the Austrian standard DIN 4074-1 (quality class 2 and cutting class S = sharp-edged).

- With metal constructions, the profiles must be made of soft, non-alloyed steel with double-sided galvanising of at least 100 g/m² according to the Austrian standard DIN 18 182-1 or DIN EN 14 195.

- The construction has to be designed to carry the weight of the ModulePanels (20.5 kg/m²) and any eventual additional loads (e. g. ceiling lights). Additional loads such as ceiling lights, multi-layer planking and other fittings must also be taken into account!

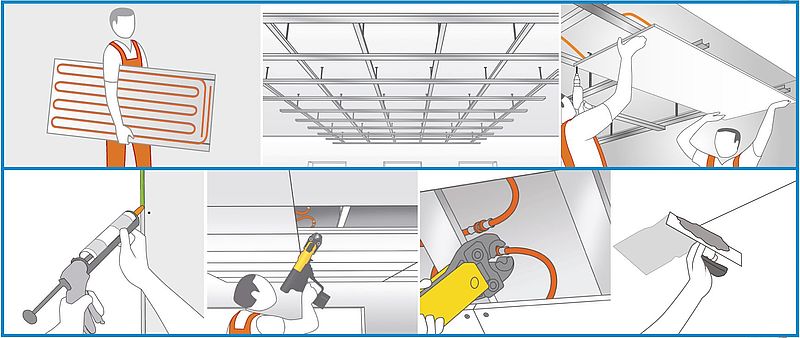

Simple and quick to install

The flexible Variotherm ModulePanels are mounted using drywall construction and can also be retrofitted. Both metal and timber structures are suitable as substructures.

How it works: One panel after another is aligned in position and screwed on. The joint adhesive on the edge completely connects the panels. The Variomodular pipe (aluminium multi-layer composite pipe) laid on the rear side is connected to the heating and cooling manifold. The cooling and heating ceiling is ready for plastering and painting.

Commonly available paints such as latex, emulsion or gloss paints can be applied to the ModulePanels. Mineral-based paints such as limewash and silicate paints must be approved by the manufacturer for use on gypsum fibre boards. The paint is usually applied to the panels in two steps.

![[Translate to English:] Variotherm Deckenkühlung/-heizung [Translate to English:] Variotherm Deckenkühlung/-heizung](/fileadmin/_processed_/a/8/csm_Deckenkuehlung1_d29955e205.jpg)

![[Translate to English:] Variotherm Deckenkühlung/-heizung Trockenbau [Translate to English:] Variotherm Deckenkühlung/-heizung Trockenbau](/fileadmin/_processed_/b/f/csm_Variotherm_Video_Moduldecke_d58826d872.jpg)